Precision and Flexibility in Aluminum Die Casting #

Aluminum die casting stands out as a manufacturing process that delivers high-precision components with complex geometries, making it a preferred choice for a wide range of industries. Its combination of strength, lightweight properties, and versatility enables the production of reliable parts for demanding applications.

Key Applications #

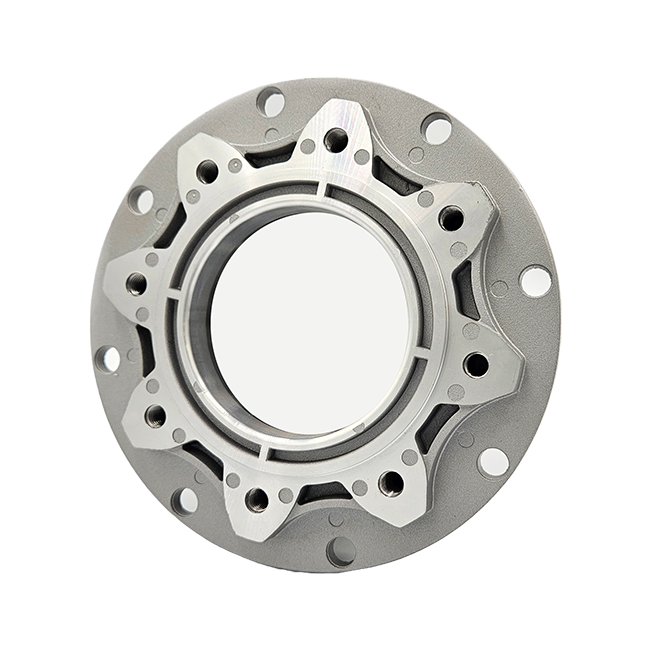

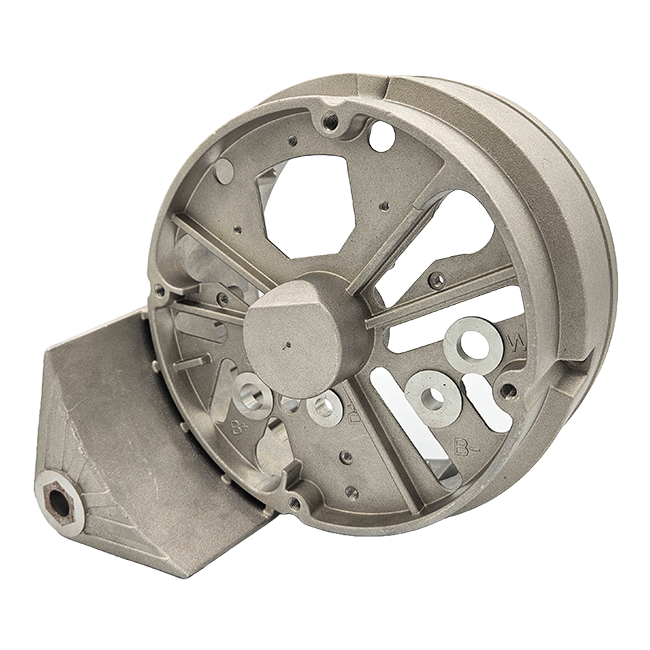

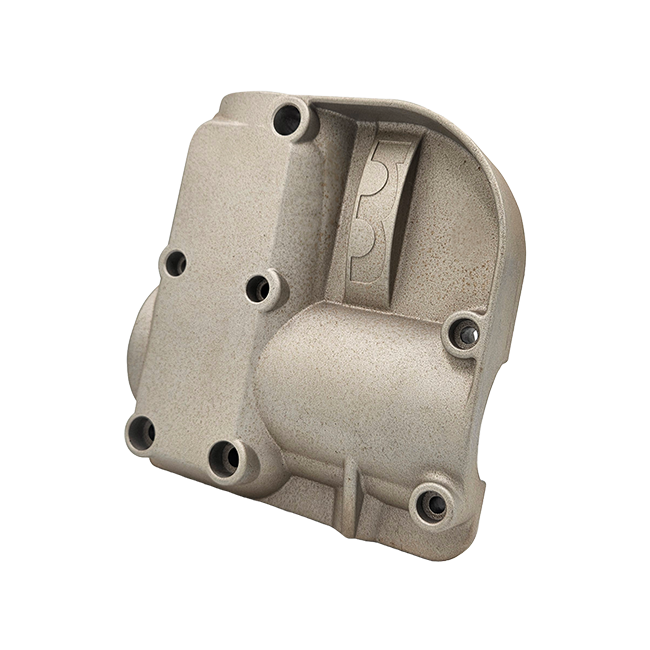

Custom aluminum die casting parts are integral to a variety of sectors, including:

- Compressor components

- Reducer gearbox housings and lids

- Hand tool components

- Packing machine parts

- Dynamotor lids

- Woodworking machine components

- LED light and lamp covers/lids

- Photographic equipment components

Features and Advantages #

Aluminum die casting is valued for its ability to produce components with:

- High dimensional accuracy and intricate shapes

- Excellent strength-to-weight ratio

- Superior thermal conductivity

- Corrosion resistance for enhanced durability

- Consistent quality in large-scale production

- Cost-efficiency for both small and large batches

These attributes make aluminum die casting suitable for automotive, aerospace, electronics, industrial machinery, and construction hardware, among other fields.

Material Options #

A range of materials is available to meet diverse project requirements:

- Aluminum alloys: ADC 1, 3, 5, 6, 10, 12, and 6061 (extruded)

- Zinc alloys: Zamak 2, 3, 5, 7

Material selection is tailored to the specific needs of each application, ensuring optimal performance and longevity.

Manufacturing Range #

Production capabilities are adaptable and can be customized according to client specifications, supporting both standard and highly specialized component designs.

Commitment to Quality and Collaboration #

A focus on delivering a broad product range and maintaining high standards of quality ensures a productive and reliable partnership for every project.

For further details or to discuss your requirements, please visit the Contact Us page.