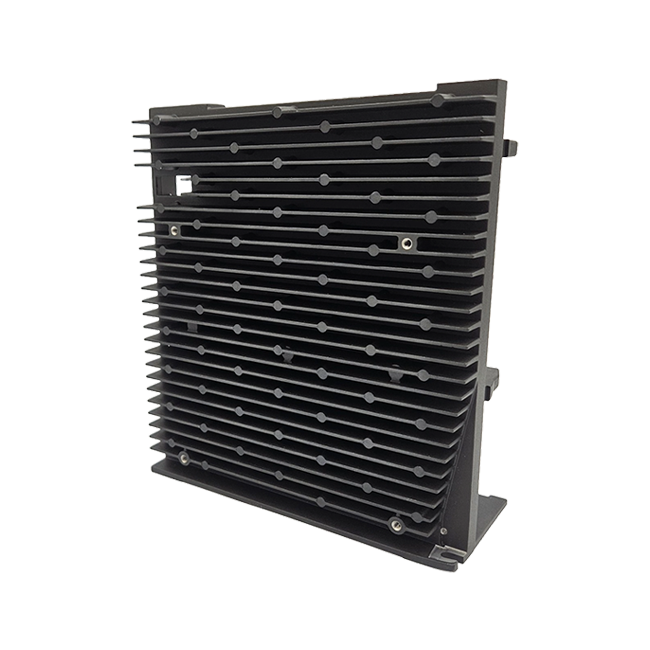

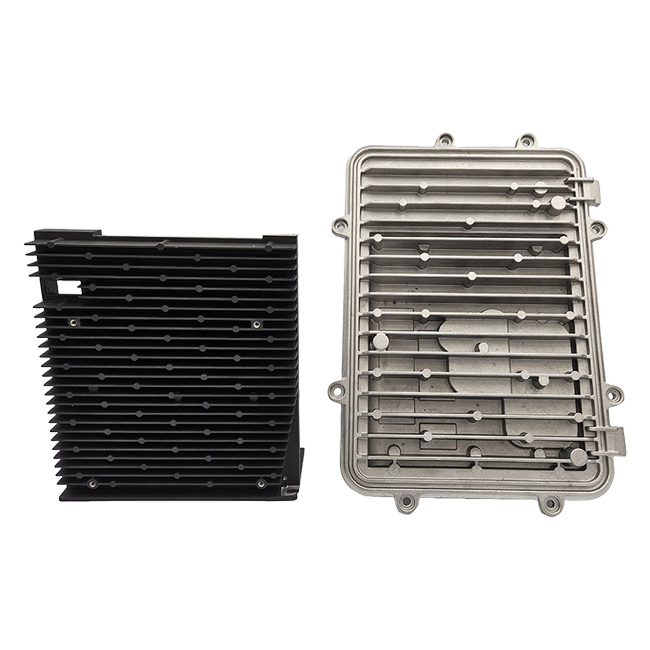

Advanced Thermal Management with Aluminum Heat Sink Plates #

Aluminum heat sink plates are essential components in modern electronic and industrial systems, providing reliable thermal management to ensure optimal performance and longevity of devices. Their versatility and efficiency make them a preferred choice across a wide range of applications.

Applications #

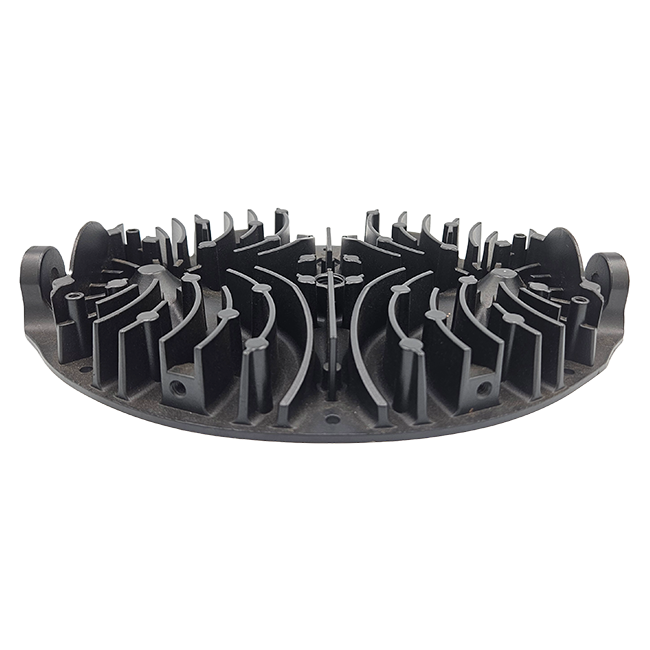

- LED Lighting Systems

- Consumer Electronics

- Automotive Industry

- Power Electronics

- Telecommunication Equipment

- Industrial Machinery

- Renewable Energy Systems

- Audio Equipment

- Aerospace & Defense

Key Features #

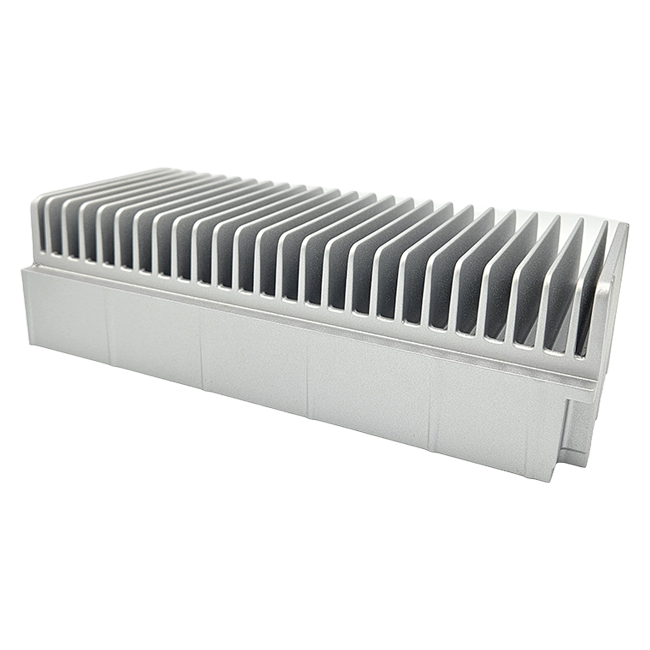

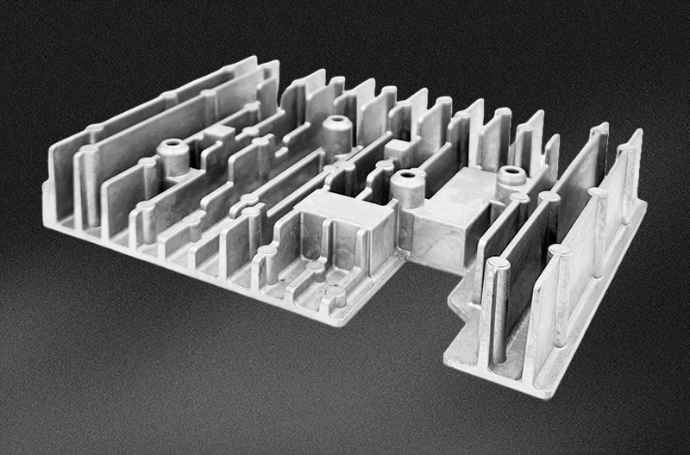

Aluminum stands out as an ideal material for heat sinks due to its excellent thermal conductivity, lightweight properties, and cost-effectiveness. It efficiently dissipates heat from electronic components, helping to maintain optimal operating temperatures and prevent overheating. The low density of aluminum makes it significantly lighter than metals like copper, reducing the overall weight of devices without sacrificing performance. Its affordability and wide availability further reinforce aluminum as the preferred choice for heat sink manufacturing across various industries.

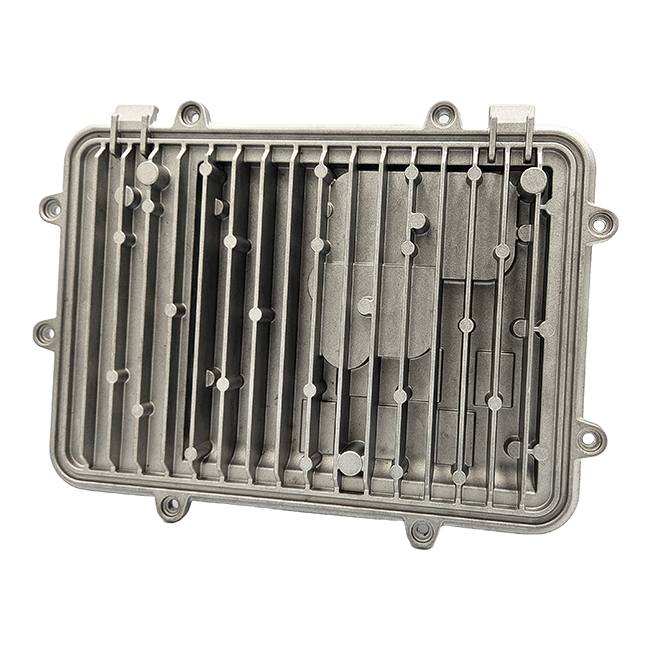

Materials #

- Aluminum Alloy: ADC 1 / 3 / 5 / 6 / 10 / 12 & 6061 (Extruded)

- Zinc Alloy: Zamak 2 / 3 / 5 / 7

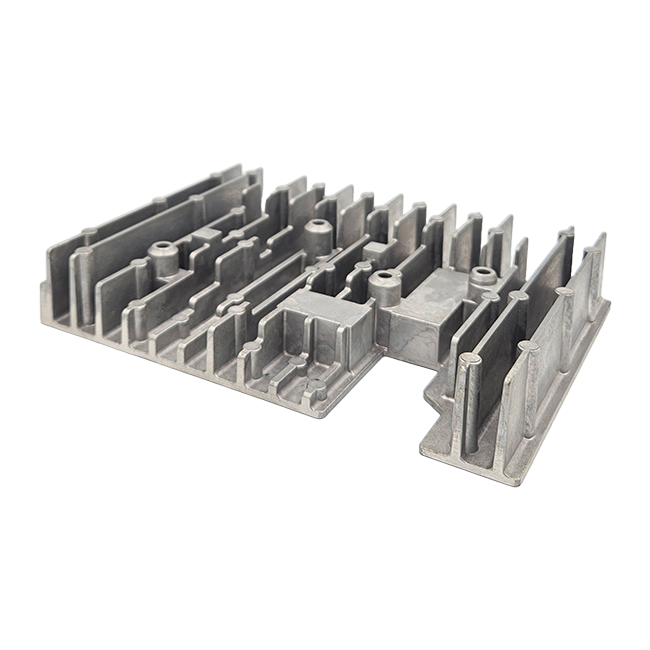

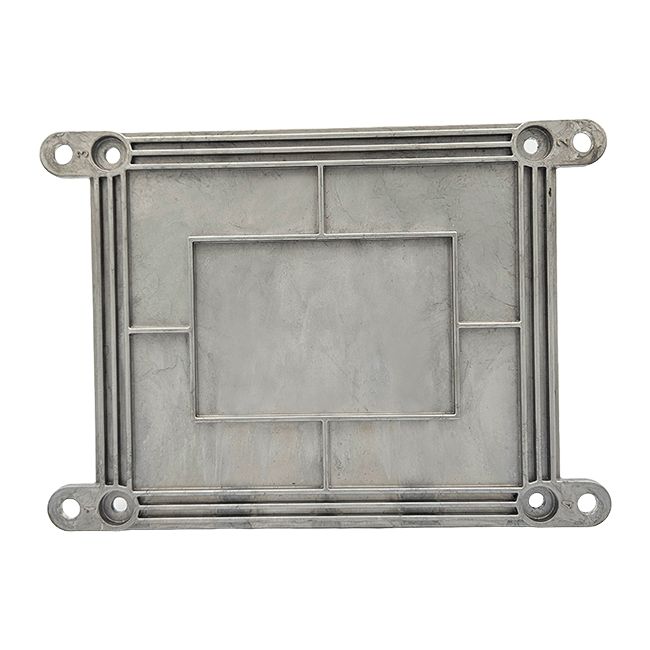

Manufacturing Capabilities #

- Customization based on customer requirements

- Die-cast machine capacity: 150T to 500T

- Heat treatment options: T3 / T6

- Surface treatments: Anodized, Sandblasting, Powder Coating

Commitment to Quality #

We are dedicated to delivering a diverse range of products with exceptional quality, ensuring a seamless and productive collaboration experience for our partners.

For more information or to discuss your specific requirements, please contact us.