Comprehensive Solutions for Aluminum and Zinc Alloy Manufacturing #

With over 20 years of experience in producing a wide range of aluminum and zinc alloy products, we have developed a robust system that integrates both production and supply chain services. This approach allows us to offer a true one-stop solution, simplifying the procurement process for our clients and ensuring a smooth, efficient experience from initial concept to final delivery.

Through our single-window service, customers benefit from comprehensive support at every stage, including both pre-production planning and after-sales assistance. Our commitment is to deliver not only diverse product options but also exceptional quality and reliability throughout the collaboration.

Die Casting Manufacturing Flow #

Our manufacturing process is designed to ensure precision, flexibility, and quality at every step. The typical workflow includes:

-

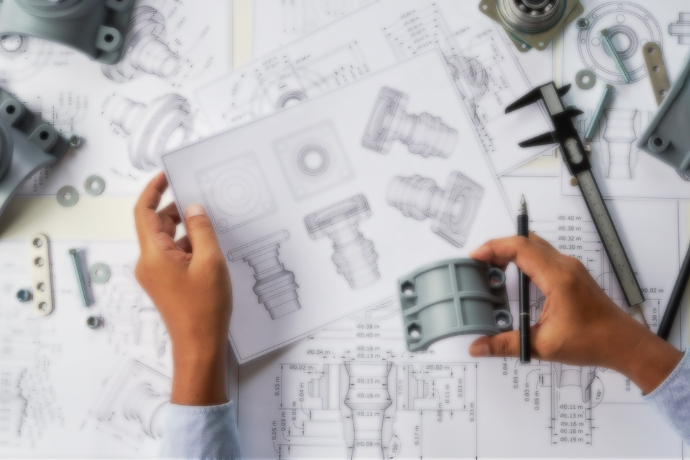

Official Drawing or Sample

We can work from your official drawings or physical samples, and also offer reverse engineering services to recreate or improve existing parts.

-

Mold/Tooling Development

Our team handles the complete cycle of mold and tooling development, from design and manufacturing to mold testing, ensuring readiness for production.

-

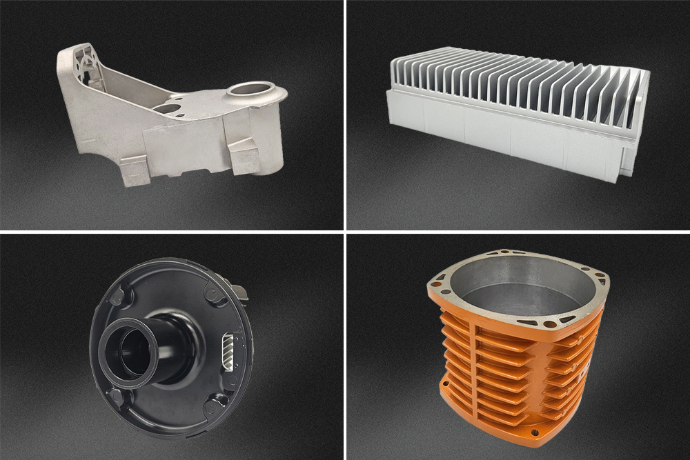

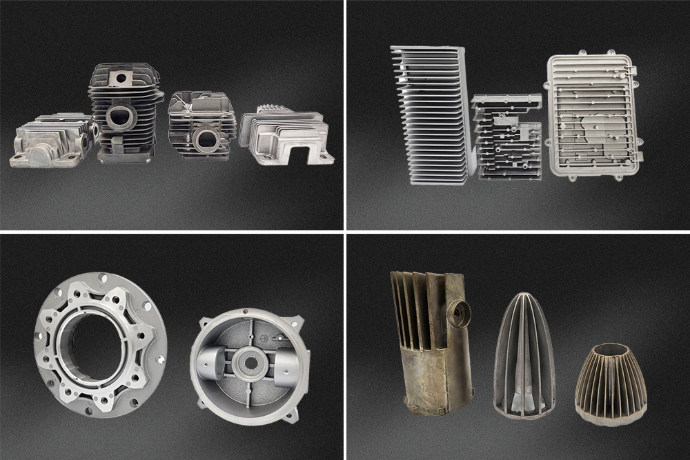

Die Casting Process

We specialize in aluminum alloy, zinc alloy, and steel-hub overmolding (composite materials), delivering high-quality cast components tailored to your requirements.

-

Secondary Machining

Post-casting, we offer a range of machining options including grinding, sand blasting, and vibration processing to achieve the desired finish and tolerances.

-

Precision CNC Machining

Our advanced CNC capabilities cover lathing, milling, and grinding, ensuring high-precision components for demanding applications.

-

Surface Treatment

We provide a variety of surface treatments, including painting, electrophoretic coating, anodizing, zinc plating, zinc-resistant treatment, and polishing, to enhance both appearance and durability.

-

Other Customized Processes

Additional services such as screen printing, pad printing, laser engraving, and plastic overmolding are available to meet specific customization needs.

How We Support Your Projects #

Our integrated approach is designed to provide a seamless experience, from initial consultation to final delivery. We are dedicated to offering a broad selection of products and maintaining high standards of quality, ensuring that every collaboration is both efficient and rewarding.

Explore Our Product Categories #

Learn More About Our Capabilities #

GRAMOS Die Casting Industrial Co., Ltd.

No. 255, Dongzhou Road, Shenkang District, Taichung City 429, Taiwan.

Email: erin.liu@gramosdiecast.com

Tel: +886-4-25130036